Glid Copper

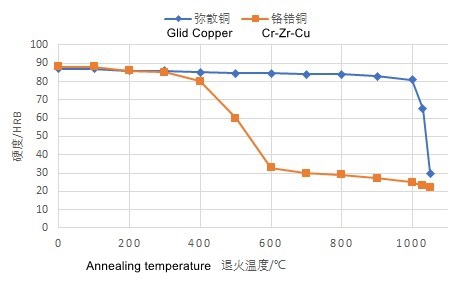

Glid Copper (Dispersion-strengthened copper alloy), also known as alumina copper, is a copper alloy that is dispersed and strengthened by nano-sized alumina particles. It has high strength, high hardness, high wear resistance, high electrical conductivity, and high thermal conductivity. In particular, its excellent high temperature performance is unmatched in copper alloys, and it maintains high strength at 900 °C. After 20 hours of 950-degree heat treatment, the metallographic structure shows no change, and the tensile strength only decreases. 8%, the hardness is only reduced by 3%, so Glid Copper will show great advantages when used at high temperatures or subjected to high temperature treatment!

Glid Copper Composition and Physical Properties

| Brand | Al | Cu | Melting Point °C | Density | Resistivity 20°C µΩ/cm | Conductivity 20°C IACS% | Tensile Strengthσb MPa | Elongation δ% | Hardness HRB | Thermal Conductivity W/m/k at 20°C | Thermal Expansion Coefficient ~450°C×10-6 | Elastic Modulus Mpa×104 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Room Temperature | 650℃ | Room Temperature | 900℃×2h Annealing | |||||||||||

| XYM-15 | 0.15 | 99.7 | 1082 | 8.81 | 1.93 | 90~95 | 400~500 | 300~400 | 10~25 | 60~75 | 58~70 | 346 | 19.5 | 10.8 |

| XYM-25 | 0.25 | 99.5 | 1082 | 8.80 | 1.99 | 86~92 | 420~550 | 320~420 | 10~25 | 65~78 | 65~75 | 334 | 19.8 | 11.5 |

| XYM-35 | 0.35 | 99.3 | 1082 | 8.79 | 2.04 | 85~90 | 450~600 | 350~450 | 8~25 | 70~80 | 70~78 | 323 | 20.0 | 12.0 |

| XYM-45 | 0.45 | 99.1 | 1082 | 8.78 | 2.08 | 82~86 | 470~620 | 370~470 | 7~25 | 75~80 | 75~82 | 313 | 20.3 | 12.7 |

| XYM-60 | 0.60 | 98.8 | 1082 | 8.78 | 2.12 | 78~83 | 480~650 | 400~500 | 5~25 | 78~85 | 78~83 | 305 | 20.4 | 14.0 |

| XYM-80 | 0.80 | 98.4 | 1082 | 8.75 | 2.15 | 76~80 | 480~650 | 400~500 | 3~20 | 78~88 | 80~85 | 298 | 20.5 | 14.5 |

Remarks: The superiority of XYM-80 is reflected in the good wear resistance.

Main Products and Specifications

Glid Copper also has good deformation processing properties, and can be used to make various forms of products such as plates, rods, wires, tubes, etc. The conventional products are as follows, and can also be customized according to the special requirements of customers.

| Glid Copper | Diameter/Thickness (mm) | Width (mm) | Length (mm) | Remarks & Special Specifications |

|---|---|---|---|---|

| Plates | 0.03-20 | 25~800 | 100~5000 | Can be customized according to requirements |

| Bars | 10~80 | 200~5000 | Can be customized according to requirements | |

| Wires | 0.08~1 | Coil | ||

| Rods | 1~10 | 200~5000 | ||

| Tubes | D5~80 | d3~75 | 500~5000 | Can be customized according to requirements |

Glid Copper Performance Introduction

-

High recrystallization temperature and good stability: The recrystallization temperature (Tagain) of industrial pure metals is generally 0.35-0.40 Tm (Tm is the melting point of the metal). The strengthening phase of the dispersion strengthened copper (Glid copper) generally has good thermal stability and chemical stability, and does not undergo any chemical change even at a high temperature close to the melting point of the metallic copper. Therefore, dispersion-strengthened copper maintains structural stability at high temperatures and has a high recrystallization temperature, T=0.9Tm (Tm is the melting point of metallic copper).

-

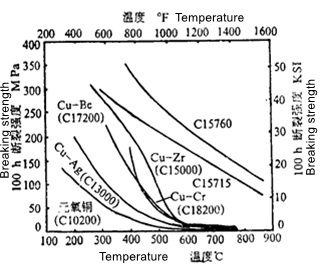

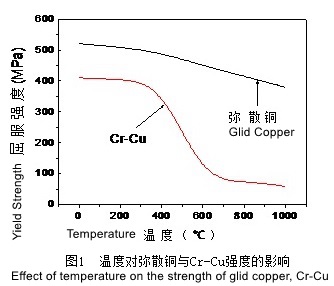

Excellent high temperature mechanical properties: A large number of strengthening particles are uniformly dispersed in the glid coppers, which has a strong hindrance to the grain boundary slip and can significantly improve the creep strength of the alloy. At the same time, hot extrusion and cold drawing cause the microstructure of the alloy to be fibrillated, and the number of transverse grain boundaries is reduced, which also significantly weakens the grain boundary slip. Therefore, the dispersion strengthened copper alloy (Glid Copper) has a high creep strength.

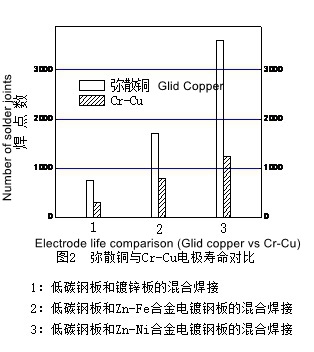

Comparison with Cr-Cu Performance

Process Flow