- tungsten, molybdenum, tantalum, niobium and rhenium,

ods-copper,cemented carbide.

Products

- Home

- Products

Products List

Ceriated Tungsten Electrodes

Thoriated Tungsten Electrodes

Lanthanated Tungsten Electrodes

Zirconiated Tungsten Electrodes

Yttriated, Pure Tungsten & Composite Electrodes

Tungsten Copper Electrodes

Tungsten Heavy Alloy Electrodes

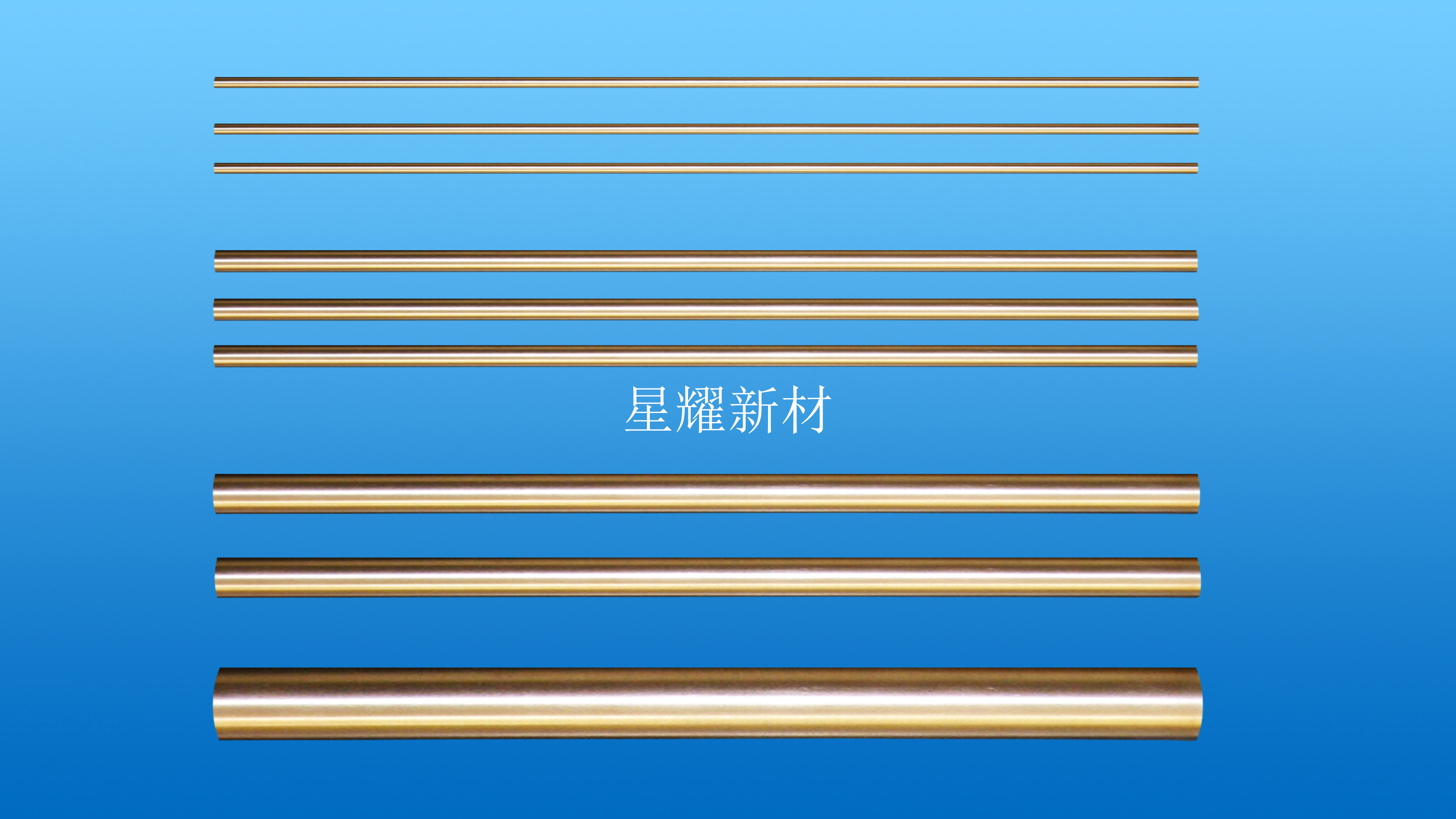

Tungsten Electrodes Rods

Molybdenum Electrodes Rods

Electrodes Packaging

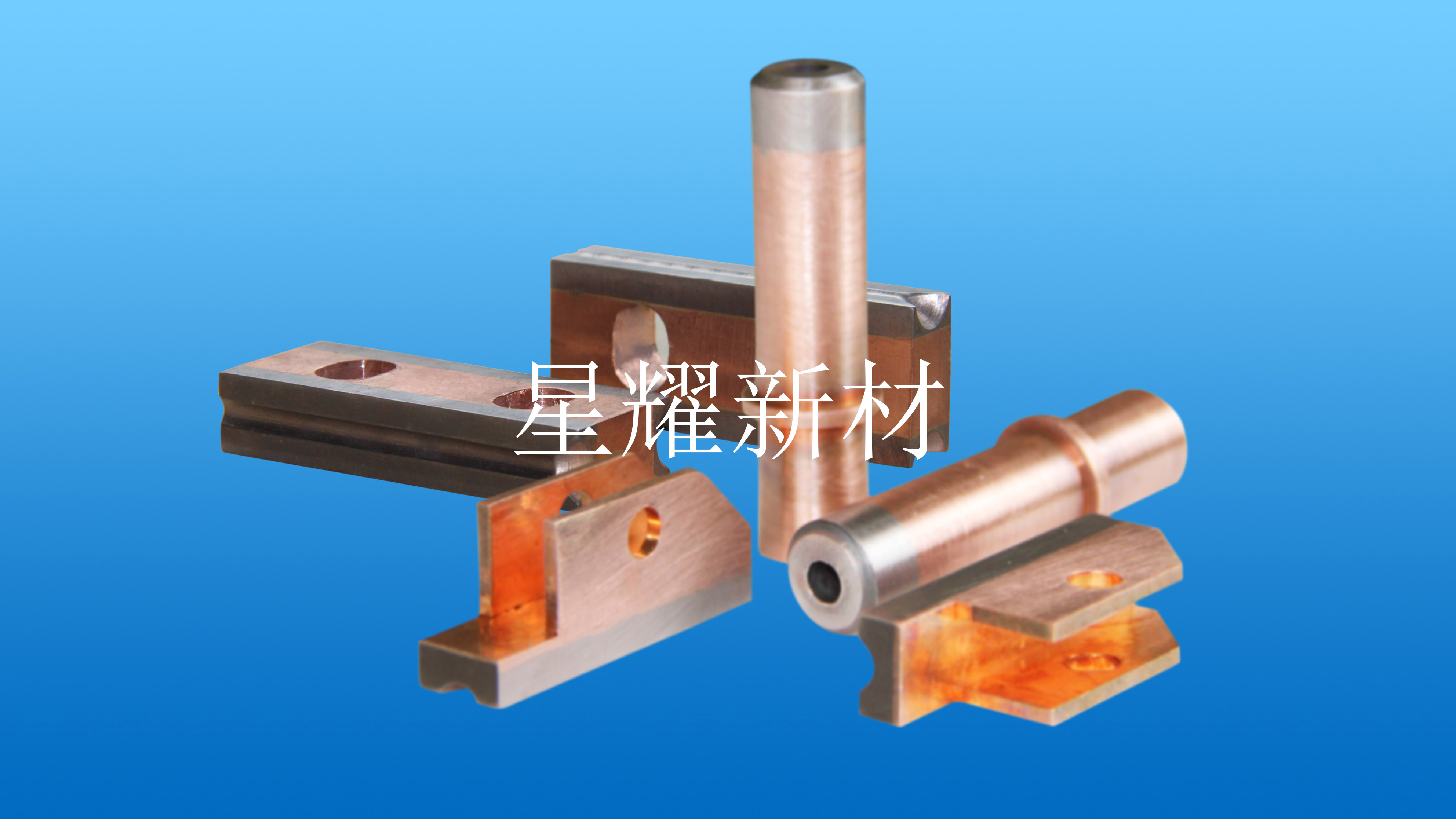

Tungsten Copper Electrodes

WCu alloy has the advantages form both tungsten and copper:good resistance for high temperature and arc erosion, high strength, high density, good electric and thermal conductivity, small thermal expansion,easy machining. It is widely used as electrodes of resistance welding and electric spark erosion cutting machines, arcing contacts and vacuum contacts in high and medium voltage breakers or vacuum interrupters.

WCu composites are offered with 7-50 wt.%Cu.

Product Standard:

GB/T 8320-200 or ASTM B 702-93 (Reapproved 2004)

Product Properties:

Physical Properties of Major Products.

|

Class |

Density |

Coefficient of thermal expansion at 20℃ |

IACS |

Thermal conductivity at 25℃ |

Hardness |

Bending Strength |

|

g/cm³≥ |

10-6/K |

%≥ |

W/M·K |

HB kgf/mm3≥ |

MPa≥ |

|

|

W93Cu07 |

17.5 |

6.3 |

26 |

172 |

270 |

1190 |

|

W90Cu10 |

17 |

6.5 |

27 |

185 |

260 |

1160 |

|

W80Cu20 |

15.4 |

8.3 |

34 |

205 |

220 |

980 |

|

W70Cu30 |

14 |

9.4 |

42 |

215 |

175 |

790 |

|

W60Cu40 |

12.8 |

11.2 |

47 |

300 |

140 |

600 |

|

W50Cu50 |

12 |

12.5 |

55 |

330 |

115 |

534 |

The softening temperature of all above materials is 900℃.

The above materials W93Cu07, W90Cu10 and W80Cu20, with high-temperature sintered tungsten skeleton and without any activating additives,are of high structure strength, good resistance of arc erosion, good electric conductivity and long-life when used as the electrodes of resistance welding and electric spark erosion cutting machines.